By Stephen Kishewitsch

Kyle Bassett doesn’t just want to build a more affordable wind turbine to provide electricity to remote villages in the developing world. He wants to re-engineer the entire process by which village power generation gets done, and his company, RMRD, which stands for Rapid Manufacturing, Rapid Deployment, won an award for the innovative way he’s going about it.

But one of the obstacles to rural electrification by conventional sources, like wind and solar, even those intended for the purpose, is deployment cost, Bassett has found.

“The main challenge with rural electrification has been the cost of manufacturing, deploying and installing technologies like solar and kilowatt-scale turbines in areas where there is no electricity. Deployment costs very quickly exceed the actual value of the generation and storage technologies.” It’s the fabrication of the mechanical parts that drives the costs up, he explained in a phone conversation, often relying on skills and production techniques only available in industrialized countries.

“So we’re trying to switch the paradigm for how these things are manufactured. I can almost entirely eliminate all the material costs, and the labour and skill required. It completely changed the economics.”

3-D printing is the key. Except for the generator itself, Mr. Bassett’s turbine uses either simple metal components available in auto shops around the world, or about ten individual parts – blade hubs, generator mount, and so on, that account for over a third of the material involved – that would normally be machined but can instead be cranked out by an inexpensive 3-D printer.

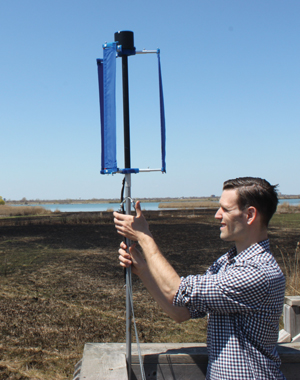

The turbine itself, instead of rigid blades, uses a Dacron or nylon fabric stretched over three fiberglass frames. In a wind the fabric forms a sail shape similar to that on a high-performance sailboat. It sounds simple, but Bassett says the design took about a dozen attempts over nearly a year, using computer-aided design, to attain aerodynamic efficiency. There again, 3-D printing greatly aided the design process, making it easy to generate prototypes.

Cost for one unit is about $300, Basset says. A small lithium polymer battery for storage adds about 15%. The whole assembly can be set up – and taken down again in case of an impending storm – in a matter of minutes.

That’s the first part of the system.

For the second part, a Kickstarter campaign opened May 15 will raise money to bring Mr. Bassett, plus a 3-D printer and the few other components that need to be sourced here, back to his remote village in Nicaragua, where he will set up a bank of turbines and use them to power the printer to print out the components for more turbines.

“We plan to install at least fifty turbines, and do a very thorough job documenting the project, as a case study for NGOs,” he said.

The turbine design, including the 3D printer instructions, is being published online for free.

Mr. Bassett says his plans have attracted a lot of attention at home as well, from off-grid cottagers and the like. He is producing a more commercial design for that market, with a manufacturing partner. His next project is a storage device, also relying on 3D printed components, which he plans to unveil at a conference in Scotland in July.

Kyle Bassett is completing a PhD thesis at the University of Windsor. For his work on electrifying remote communities he was awarded $25,000 in early May as the winner of the David McFadden Energy Entrepreneur Challenge at the Ontario Centres of Excellence annual Discovery Conference in Toronto. The theme for this year’s challenge was “Meeting the Energy Challenge of Remote Communities.” Students were to develop sustainable electricity generation technology or distribution systems that meet the needs of remote communities rapidly and are easy to install and maintain in Canada and other parts of the world.

Kyle Bassett is completing a PhD thesis at the University of Windsor. For his work on electrifying remote communities he was awarded $25,000 in early May as the winner of the David McFadden Energy Entrepreneur Challenge at the Ontario Centres of Excellence annual Discovery Conference in Toronto. The theme for this year’s challenge was “Meeting the Energy Challenge of Remote Communities.” Students were to develop sustainable electricity generation technology or distribution systems that meet the needs of remote communities rapidly and are easy to install and maintain in Canada and other parts of the world.

The David McFadden Energy Entrepreneur Challenge was introduced last year to honour previous OCE Chair David McFadden. The challenge aims to support student innovation and entrepreneurship while supporting David’s philosophy of innovation: That new business ideas be economically viable while also leading to the betterment of society.