By Stephen Kishewitsch

We like our veggies in nice crispy salads, not so much when they turn into a biology experiment in the back of the fridge. But organic waste, from uneaten food to animal manure, still has many uses. Rather than letting it ooze leachate and exhale greenhouse gases in untapped landfills, the Canadian Biogas Association (CBA) is seeking to Close the Loop – let it generate renewable energy, not to mention high-quality fertilizer, while reducing pollution.

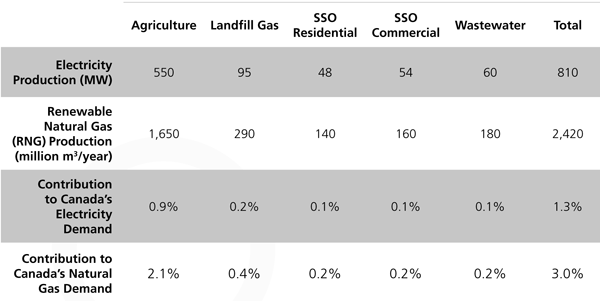

A 2013 study by the association found a potential 810 MW of electricity production across the country using biogas for generation. Direct capital investment would be some $7 billion. A side benefit would be a reduction of 37.5 million tonnes of carbon dioxide equivalent a year.

Through the FIT program, the agricultural sector in Ontario has been able to develop a substantial number of opportunities to turn organic waste into electricity (see map). Most are farming operations, which use their own by-product waste, such as manure, and/or truck organic material in from other sources, such as commercial food processing waste, and use the gas to generate electricity.

Through the FIT program, the agricultural sector in Ontario has been able to develop a substantial number of opportunities to turn organic waste into electricity (see map). Most are farming operations, which use their own by-product waste, such as manure, and/or truck organic material in from other sources, such as commercial food processing waste, and use the gas to generate electricity.

Still, the organization sees more potential to be opened. “We’re working to build both demand and supply of renewable natural gas (RNG),” says Stephanie Thorson, in charge of the Closing the Loop program. “We’re looking for market leaders that can both generate and use RNG. We’re targeting municipalities, and large scale food processors to some degree. It’s mostly a marketing exercise. We’re trying to raise the profile and get both suppliers and customers into the system, drum up demand. There’s a lot of potential in the transportation sector, where nobody knows what RNG is.”

Still, the organization sees more potential to be opened. “We’re working to build both demand and supply of renewable natural gas (RNG),” says Stephanie Thorson, in charge of the Closing the Loop program. “We’re looking for market leaders that can both generate and use RNG. We’re targeting municipalities, and large scale food processors to some degree. It’s mostly a marketing exercise. We’re trying to raise the profile and get both suppliers and customers into the system, drum up demand. There’s a lot of potential in the transportation sector, where nobody knows what RNG is.”

Potential sources of organic feedstock can be grouped into agricultural organics, residential source separated organics (SSOs), commercial SSOs, landfill gas (LFG), and wastewater treatment residuals. As the 2013 study notes, a biogas project can be highly specialized, utilizing any one of these feedstocks, or designed as an integrated, multi-purpose system accepting and processing multiple materials for a range of energy applications. In the case of wastewater, at present only Hamilton’s wastewater treatment plant is generating biogas, which, purified to just methane, is injected into Union Gas’ system and withdrawn again for uses such as the city’s transit fleet.

Ms. Thorson draws a comparison with Redeem, a service offered by Clean Energy in the United States, which feeds biogas into the interstate pipeline. A beneficiary of a program by the US federal government, the RNG, a 10%-90% blend of renewable and conventional content, is sold at the same price as regular CNG. Blended RNG here costs more, 65 cents compared to 60 cents, for the energy equivalent of litre of gasoline. The CBA is trying to bring Canada into the RNG market with a comparable program in Canada.

A landfill gas operation in Quebec, owned by Progressive Waste solutions, is using the natural gas pipeline to wheel its RNG to users in California.

The CBA has also made some recommendations to the IESO regarding FIT 4 and particular concerns highlighted by the biogas sector; for example, a procurement schedule that provides contract offers in 2015 enabling certain and timely development of biogas projects and securing of feedstock agreements. At time of publication the CBA has not yet heard back on its recommendations.

See also FIT 4: Enhancements to the FIT program, elsewhere this issue.