By Ron Oberth, President, Organization of CANDU Industries

The companies in Canada’s nuclear supply chain, an essential part of the nuclear power business, are the source of a considerable volume of high tech jobs and innovation in Canada. Including more than 200 private sector companies, this specialized sector manufactures major components and specialized equipment for nuclear power stations and provides engineering and support services to the 20 operating CANDU nuclear power plants in Canada as well as to CANDU and LWR (Light Water Reactor) nuclear plants in offshore markets. This supply chain includes a number of quiet Canadian success stories, and is well-positioned to supply the next round of refurbishment projects and new nuclear construction projects in Canada and around the world.

Seasoned through years of work on projects that require a high degree of collaboration, this group of companies have developed the ability to work closely together on projects, often supplying components to one another, while maintaining their distinct identities – in some cases competing against one another for domestic work. This combination of interconnectedness and private sector discipline creates strong incentives to ensure that the provision of equipment and services meet the highest standards of quality and reliability. Nuclear suppliers are located mainly in Ontario, the heartland of Canada’s nuclear industry, and collectively employ more than 30,000 highly trained and specialized people. Many of these individuals have unique skills and experience required to work in the nuclear sector with its rigorous standards for quality and precision. Around 90% of these companies are so-called SMEs (Small and Medium-sized Enterprises) – defined by the Canadian government as companies of less than 500 employees.

Canadian nuclear suppliers are often clustered around larger so-called “tier one suppliers.” For example, there is a cluster of suppliers in the Mississauga / Oakville / Burlington region in order to facilitate access to Mississauga–based Candu Energy (formerly the AECL Commercial Reactor Division). Other clusters of suppliers have emerged in Cambridge, Peterborough, Niagara, and Durham Region and Bruce County. Another group of relatively small leading edge technology companies has evolved in the Ottawa valley – some of which are spin-offs from the AECL National Laboratory.

The supply chain is growing. Planned refurbishments and life extensions of Ontario's fleet of 18 CANDU units along with the anticipated construction of two new nuclear units at Darlington is now spurring interest from large international players involved in nuclear construction management, radiation protection, waste management, and balance of plant equipment. Several large international companies have invested in Canada and have expanded their Canadian acquisitions to international scale. A good recent example of this is UK-based Rolls-Royce Civil Nuclear that is growing its newly acquired Peterborough operation through expansion of its existing services to the Canadian nuclear market and by using its recent successful delivery of a unique waste handling system to AECL to establish itself as an international supplier of nuclear waste management equipment.

Innovation has become Canada’s key differentiator in the increasingly global and competitive nuclear market – a field that is facing downward cost pressure to make nuclear power cost competitive in an environment characterized by low cost natural gas and capital constraints. Nevertheless Canadian suppliers are confident that they can succeed in both Canadian and international markets by building on a tradition of nuclear innovation that has been incubated at the AECL National Laboratory, supported by a strong university network and facilitated by organizations such as the Ontario Centers of Excellence.

The outlook for nuclear investment in Ontario is very positive. Ontario plans to continue to rely on base load nuclear for over 50% of its energy needs. Over the next 10 years investment in Darlington refurbishment, life extension of Bruce units 3-8, and construction of two new nuclear units at Darlington could easily reach $20 billion. Approximately 25% of that amount involves the purchase of equipment and components – an estimated $5 billion. We expect that 70-80% of supply would be Canadian, yielding revenue of approximately $4 billion over the next 10 years in Canada. These numbers are very attractive to SME owners and investors. It also means around 10,000 direct new jobs in the supply chain, which is great news for local communities across Ontario.

Following are some examples of nuclear supply chain companies operating in Ontario:

Laker Energy Products, Burlington Ontario:

Incorporated in 1995, Laker operates a fully integrated high-precision machining, assembly and test facility manufacturing CANDU reactor components. Currently employing 22 people, over the years, the firm has supplied over $100 million in equipment, material and components with approximately 80% being exported to Romania, China, South Korea and Argentina. The company has grown through four facilities and is set to expand again by applying its expertise in high quality manufacturing learned in the nuclear industry to other comparable industries including aerospace and military.

Incorporated in 1995, Laker operates a fully integrated high-precision machining, assembly and test facility manufacturing CANDU reactor components. Currently employing 22 people, over the years, the firm has supplied over $100 million in equipment, material and components with approximately 80% being exported to Romania, China, South Korea and Argentina. The company has grown through four facilities and is set to expand again by applying its expertise in high quality manufacturing learned in the nuclear industry to other comparable industries including aerospace and military.

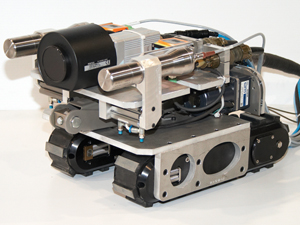

Promation Nuclear Ltd, Oakville, Ontario:

Promation Nuclear, with its team of 80 engineers and technicians, supplies engineered tooling solutions for CANDU reactor technology for service, repair or refurbishment of fuel channels and other reactor components.

Promation Nuclear, with its team of 80 engineers and technicians, supplies engineered tooling solutions for CANDU reactor technology for service, repair or refurbishment of fuel channels and other reactor components.

Its innovative robotic tools are capable of remote operation in a hot radioactive environment thus eliminating or substantially reducing exposure of operators and maintenance personnel. Promation has supplied its product to domestic customers and plans to move into offshore CANDU markets for its tooling products.

Its innovative robotic tools are capable of remote operation in a hot radioactive environment thus eliminating or substantially reducing exposure of operators and maintenance personnel. Promation has supplied its product to domestic customers and plans to move into offshore CANDU markets for its tooling products.

Liburdi Automation Inc., Stoney Creek, Ontario:

Liburdi has had a long history in providing equipment and service to the Canadian nuclear market dating back to the 1970’s. More recently Liburdi has expanded its sales to nuclear projects in export as well as domestic markets. Some examples of these projects are: the “weld over lay” as part of the repair of the NRU in Chalk River, the bellows and pressure tube replacements at Bruce Power, Point Lepreau and the Wolsong 1 CANDU plant in South Korea. Liburdi also provided complete welding solutions, including process development, welding equipment and on-site support for the steam generator replacement at Bruce Power and for primary piping replacements at six LWR reactors in China and South Korea. Liburdi employs 65 people at its Stoney Creek plant.

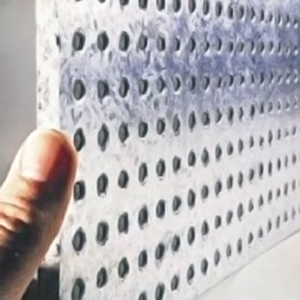

DuraSystems, Vaughan, Ontario:

DuraSystems has become a world leader in the design and manufacturing of passive fire protection systems though incorporating years of industry experience and knowledge. The company provides specialized and unique designs to protect valuable assets in the nuclear power, resource recovery (including offshore platforms), transportation and related industries across North America and the globe.

DuraSystems has become a world leader in the design and manufacturing of passive fire protection systems though incorporating years of industry experience and knowledge. The company provides specialized and unique designs to protect valuable assets in the nuclear power, resource recovery (including offshore platforms), transportation and related industries across North America and the globe.

Rolls-Royce Civil Nuclear Canada, Peterborough, Ontario:

Rolls-Royce Civil Nuclear Canada designs, builds and supports specialty equipment for the world-wide nuclear industry including waste management equipment, refurbishment tooling and components for new-build reactors. Located in Peterborough, the company has invested in acquiring a comprehensive package of nuclear Quality Assurance registrations including the prestigious “N stamp” and has earned the Rolls-Royce group label “trusted to deliver excellence.” Rolls-Royce Civil Nuclear Canada is increasingly seen within the Canadian nuclear industry as a full service provider backed by the wider capabilities of the broader nuclear group within Rolls-Royce.

Rolls-Royce Civil Nuclear Canada designs, builds and supports specialty equipment for the world-wide nuclear industry including waste management equipment, refurbishment tooling and components for new-build reactors. Located in Peterborough, the company has invested in acquiring a comprehensive package of nuclear Quality Assurance registrations including the prestigious “N stamp” and has earned the Rolls-Royce group label “trusted to deliver excellence.” Rolls-Royce Civil Nuclear Canada is increasingly seen within the Canadian nuclear industry as a full service provider backed by the wider capabilities of the broader nuclear group within Rolls-Royce.