Hydro One Networks Inc. and a group of generators using biogas as a fuel have completed a research project that will help them make more finely tuned decisions about what kinds of protection and control systems they need to use in future. The benefits could include greater grid reliability, lower capital costs, and fewer unnecessary shutdowns of generation equipment.

Known as the “Grid Connections Monitoring Project,” the idea for the initiative has been under development for several years. The formal study period began in 2011. The objectives of the monitoring project were:

Known as the “Grid Connections Monitoring Project,” the idea for the initiative has been under development for several years. The formal study period began in 2011. The objectives of the monitoring project were:

1. To characterize the electrical performance of utility feeders with connected biogas projects, and

2. To collect power quality data and assess performance and electrical characteristics associated with behavior/response of synchronous generators (biogas) and the protection systems during utility feeder faults and/or disturbances.

The project scope included a 6-month data collection period focused on three biogas generator sites and associated utility feeders. The data collection was intended to:

a) Identify power quality issues

b) Optimize generator protection performance to ensure proper protection while minimizing nuisance trips

c) Identify the capability of the synchronous generator to withstand utility system disturbances and recommend suitable tolerance limits, and

d) Determine the adequacy of interconnection (intertie) protections.

The Biogas Association had expressed concern that HONI's initial set of technical requirements for small biogas projects, required transfer trip and required directional relaying in cases where the reverse fault current through reclosers exceeded thresholds. Transfer trip protection schemes are systems designed to disconnect islanded electrical source by sending a signal to a remote part of the system to implement the disconnection. The net impact to small biogas projects (under 500kW) of such requirements is equipment upgrades and significant cost increases that are not scalable to small projects. $120,000 to $1 million in added costs for a $2-3 million project would not be unusual.

A proposal for monitoring interconnection protections, distribution feeder characteristics, and generator performances was put forward to Hydro One for biogas projects under 500kW that included the following:

a) Interconnection protection – equipment designed to detect all faults on the feeder

b) Enhanced local anti-islanding protection – secondary measures to prevent islanding situations, designed to disconnect the DG when there is no fault on the grid.

The proposal was accepted by Hydro One for the purposes of the study. Costs were in the range of $50,000 to $150,000 per project.

The Biogas Association believes that under the current rules, from a DG perspective, the issues are considerable:

1. Protection settings are not streamlined or uniform

2. Synchronous generators are susceptible to unbalanced conditions

3. These conditions prompt questions as to the impact to DG on:

a) Ability to develop accurate protection designs that maintain protection while minimizing trip events, and

b) Reliability of operations in existing environment

› Power quality

› Momentary interruptions.

From a utility perspective of course the connection of distributed generators raises a number of questions related to reliability of supply and power quality. Outages on rural distribution systems where biogas generators are usually connected, although affecting a relatively small number of people, can be complicated by the single phase structure of most lines in such areas, and the likelihood of having only single pole re-closers to isolate faults.

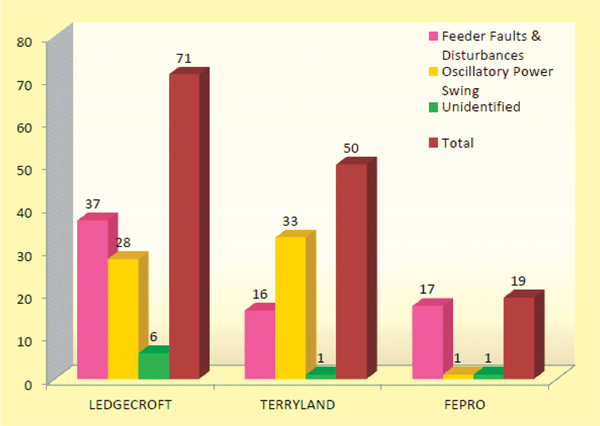

The study focused on three Biogas DG sites: Terryland Farms, Fepro Farms, and Ledgecroft Farms. Monitoring equipment included ION power quality meters installed at both the DS and DG for all 3 sites.

The approach to data collection and analysis included:

• Consultants captured records weekly at DG sites

• Oscilliograph records capturing waveforms during trips

• Sequence of event records

• Data sharing between Hydro One and Biogas consultants.

Following six months of data collection, the study authors presented their initial findings. A key statement included the following:

Event analysis demonstrated a large number of correct/incorrect trip events caused by:

• Faults occurring on the distribution feeder

• Sensitive interconnection and/or generator protection relay

• Prime mover’s internal combustion abnormalities

• Voltage and current imbalances on the distribution feeders because of single phase loads.

Initial recommendations were to “Consider continuing monitoring for issues unresolved,” and to “Make the raw monitoring data available for research purposes.”

The research found that improved precision in determining appropriate protection design, settings, and protocols would be beneficial. Recommendations in this area included:

• Accurate information exchange between DG and Utility

• Develop a protection standard and setting guide

• Settings for protection elements must be appropriately selected for generators at the design stage. These settings should be intended to:

• provide adequate generator protection

• minimize protection coordination issues

• reduce costs and

• improve overall performance and operations.

In terms of the reliability of Utility supply / DG operation, the researchers found that:

• DG customers are sensitive to irregularities

• DG protections responded to all faults as designed

• No negative impacts to the utility feeder or power quality for existing customers were observed as a result of the lower cost protection system

• Monitoring capabilities proved beneficial for all.

The researchers recommended further that designers and Hydro One work together to:

• Design protections within limits that avoid problems

• Use data capture to further improve reliability.

In terms of power quality the study found no adverse effect on total harmonic distortion. However, excessive over-tripping on vector shift and faults were found. In addition, there were power swings of undetermined cause. The group recommends further work to address issues associated with vector shift, increased time delays taking into account decaying fault current, and further investigation into the causes of and solutions for power swings.

Finally, in terms of overall protection performance, the study found that “DG protections responded to all faults where required,” and that the utility’s equipment was reasonably well protected even during fault situations: “utility protection performed satisfactorily during the study period.”

The study noted that minor improvements were made to set points, time delays and protection logic, and that no significant upgrades were made to the distribution system to connect DG’s.

In general, the study’s authors conclude that that “small numbers of biogas generators may be installed without significant upgrades to the distribution system.” This should be welcome news to anyone concerned about connecting this kind of generation while keeping costs under control in the Ontario context.

See related article, “Hydro One receives first round of input on connection standards, holds workshop,” IPPSO FACTO, June 2009.

The final report is expected to be released shortly.