An innovative Canadian company is well on its way to developing the technology to convert carbon dioxide (CO2) emissions into marketable products like biodiesel and other green fuels. Pond Biofuels, based in Toronto, uses ordinary algae, water and light to accomplish this remarkable feat, transforming waste into a resource. Their process could not only make thermal power generation carbon neutral, but it could eliminate much of the need for burning high carbon fossil fuels like coal and oil in the first place. “This holds the potential to make carbon capture an attractive companion to thermal power generation, or for any number of carbon-intensive industrial processes,” said APPrO Executive Director Jake Brooks.

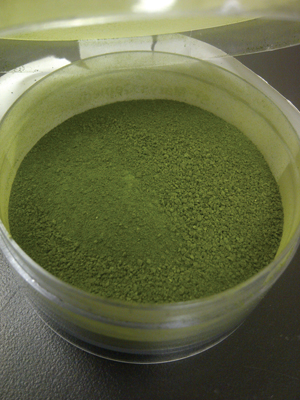

At a demonstration project attached to the St. Mary’s Cement plant near Toronto, company founders Max Kolesnik and Steven Martin of Pond Biofuels have set up a tank containing 10,000 litres of water and tonnes of live algae. Gas laden with CO2 from the cement plant’s smokestack is pumped directly into the algae tanks. There, combined with light, the algae grows steadily and works its magic converting waste into green fuel. The output is a fine powder, resembling green flour. This powder can be burned like coal or wood, or converted into biodiesel or any number of fuels that can be substituted for petroleum products.

In fact, the US government has recently certified algae-based biofuel as safe for use in commercial and military aircraft, in concentrations up to 50%. In another confirmation of the technology's viability, Ontario’s Ministry of the Environment has examined the gas released from Pond Biofuels’ algae tanks, and found it to be environmentally acceptable. In fact, the emissions are rich in oxygen and may represent another possible revenue stream for the growers of algae.

Although it has long been known that ordinary micro-algae can be used to capture CO2 and convert it into useful compounds, the technology to harness it for industrial scale operations is relatively new. In fact, algae has been responsible for converting most of the planet’s atmospheric carbon into breathable oxygen since the dawn of life. Algae employ photosynthesis, the same process that is basic to most green plants, in which sunlight is used to convert water and carbon dioxide into oxygen and fuel.

Behind the company’s invention are several years of intense work on the design of the algae tank and a number of related patents. Rather than growing algae outdoors in open ponds, the inventors believe deeper indoor tanks will produce more dependable results, and take up much less land area. Their tanks, called bioreactors, ensure optimum conditions for the cultivation of algae, and full control over inputs and outputs. Notably, although algae needs light to grow, it does not depend on the same frequencies of light that are used by solar photovoltaic panels.

In fact there are many companies working on algae-based technology around the world. It might be said that there is a kind of a race to see whose technology will achieve commercial scale first. Apparently algae is much more efficient at converting carbon dioxide to carbohydrates than are trees or other land-based plants. Martin and Kolesnik contend that the methods of cultivating algae are well-known across the scientific community. The US government invested millions of dollars in the 1980’s and 1990’s into a biofuels research program that was heavily focused on biodiesel production from algae. The final report of the Aquatic Species Program, released in 1998, concluded that certain species of algae were highly efficient at consuming carbon and that reliable production of algae in land-based open ponds was technically feasible. The research, which is essentially in the public domain today, identified a number of key factors influencing productivity. The technological challenges are mostly related to feeding light and carbon dioxide to the algae, and efficiently handling the large volumes of water and biomass.

One of the challenges in cultivating algae for commercial fuel production is efficiently collecting and delivering light. Pond Biofuels uses a system of “light guides” at its demonstration project in Ontario, combined with LED lighting immersed in waterproof tubes inside the bioreactor. In the future, they envision sizable solar reflectors collecting large amounts of sunlight in the area of the bioreactor. Dichroic reflectors could be used to direct part of the light spectrum to the algae and part of the spectrum to photovoltaic panels, thus deriving significantly more value from sunlight than today’s solar photovoltaic panels can achieve on their own.

The technology is flexible in terms of the source of light. If more sunlight is available, there is little or no need for use of artificial light to promote growth of the algae. On the other hand, if electricity prices are low, at off-peak times for example, then high efficiency electrical lights can be used to speed the growth of the algae at night. Affecting the power grid in a way that is similar to the addition of electric vehicles, the growth of this technology could allow off peak power to be used for production of high value transportation fuel.

Undoubtedly there are a number of financial challenges to overcome. How expensive will it be to process the green powder into liquid fuel in large volumes? Can the necessary light capture and redirection be implemented easily on a large scale? Will the separation and drying of the algae add a lot to the cost of the system? The bright minds at Pond Biofuels firmly believe these are reasonable challenges that can be tackled largely by adapting known technology developed for biofuel production, solar energy collection, and waste water treatment. The proponents are currently raising money for a much larger scale demonstration project during which they plan to refine their techniques and continue to demonstrate the viability of the concept. A coal-fired power plant in Pennsylvania has volunteered to connect its stack to one of the next bioreactors.

If this technology proves as economically attractive as its proponents hope, algae-based carbon capture could create a new future for thermal power generation, making carbon into a re-usable energy carrier, much like the role some futurists have envisioned for hydrogen.

These Canadian pioneers may be on to something that could help green up industry all over the world, and put the brakes on climate change. Some might say that algae has been waiting a long time to get the recognition it deserves.

See also “Hydrogen from algae on the horizon,” IPPSO FACTO April 2001, page 34, and “Algae used to scrub plant emissions,” IPPSO FACTO, February 2006, page 36.

For more information, see http://www.pondbiofuels.com/ and http://www.nrel.gov/docs/legosti/fy98/24190.pdf