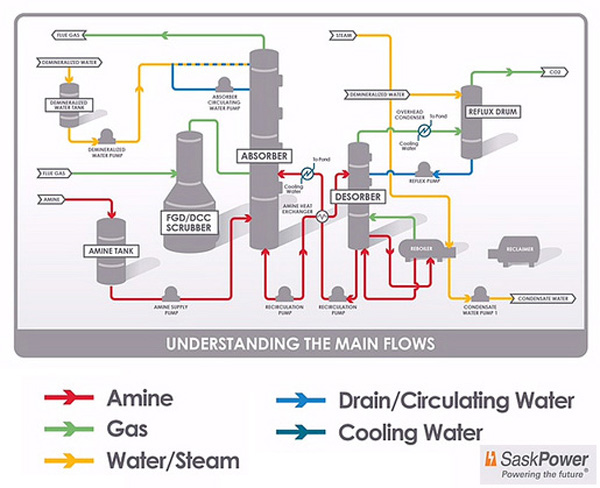

SaskPower and its Boundary Dam Unit 3 have received POWER magazine’s Plant of the Year award for 2015, for the facility’s carbon capture and sequestration system. The unit, with a capacity of 100 MW, uses an amine absorption system to extract CO2 from the exhaust gases. Some of the CO2 is transported by pipeline to nearby oil fields in southern Saskatchewan to be used for enhanced oil recovery. CO2 not used for enhanced oil recovery will be stored in the Aquistore Project, a nearby layer of brine-filled sandstone called the Deadwood Formation 3.4 kilometres deep. Located near Estevan, Saskatchewan, Aquistore is administered by the Petroleum Technology Research Centre (PTRC), which will manage the CO2 storage and monitoring.

SaskPower and its Boundary Dam Unit 3 have received POWER magazine’s Plant of the Year award for 2015, for the facility’s carbon capture and sequestration system. The unit, with a capacity of 100 MW, uses an amine absorption system to extract CO2 from the exhaust gases. Some of the CO2 is transported by pipeline to nearby oil fields in southern Saskatchewan to be used for enhanced oil recovery. CO2 not used for enhanced oil recovery will be stored in the Aquistore Project, a nearby layer of brine-filled sandstone called the Deadwood Formation 3.4 kilometres deep. Located near Estevan, Saskatchewan, Aquistore is administered by the Petroleum Technology Research Centre (PTRC), which will manage the CO2 storage and monitoring.

Sulphur dioxide is also captured, converted to sulphuric acid and sold for industrial use. Fly ash, a by-product of coal combustion, will also be sold for use in ready-mix concrete, pre-cast structures and concrete products.

Sulphur dioxide is also captured, converted to sulphuric acid and sold for industrial use. Fly ash, a by-product of coal combustion, will also be sold for use in ready-mix concrete, pre-cast structures and concrete products.

SaskPower also has a smaller-scale Carbon Capture Test Facility (CCTF), officially launched next door to its Unit 3 sister June 18.

“SaskPower can now offer access to this unique facility for companies to develop and test carbon capture and storage technologies,” said Premier Brad Wall. “This will continue to bring international interest to Saskatchewan and give us prime access to the next generation of CCS innovation.”

Built in partnership with Mitsubishi Hitachi Power Systems, Ltd., the CCTF is a high-tech laboratory that uses a small amount of exhaust (flue) gas from the neighbouring Shand Power Station and allows researchers to test equipment, chemical innovation and engineering designs in a highly controlled environment.

Mitsubishi Hitachi Power Systems, Ltd. will be the CCTF’s first client. “We’re pleased to be working with SaskPower on this initiative”, said Yasuo Fujitani, Senior Executive Vice President of Mitsubishi Hitachi Power Systems, Ltd. “We will be using our time in the CCTF tvo test our new amine solution.” Amine is the chemical solvent at the core of many CCS processes, such as the one currently operating at Boundary Dam Power Station.

The CCTF is a modular facility, where many individual parts can be isolated, modified and operated to test specific carbon capture technologies. Using its measurement tools and a data system which continually records operating conditions at “a hundred locations,” proponents say, “Companies will be able to track how their particular technology performs over time and in response to realistic commercial operating conditions.”